Neodymium madaidaicin maganadisu ana amfani da shi ne don mai kiyaye lokaci, makirufo, lasifika, sadarwa ta gani, kayan aiki da mita, likita, agogo, wayar salula, firikwensin, da sauransu.

Don maganadisu na Neodymium gabaɗaya, girman kowane shugabanci ya wuce 1mm kuma haƙuri shine +/-0.1 mm ko ƙarami zuwa +/-0.05 mm, wanda za'a iya samarwa ta kayan aikin samarwa na gabaɗaya don maganadisu na NdFeB. Ga Neodymium madaidaicin maganadisu, fasahar samarwa ta bambanta sosai. Na farko, a cikinNeodymium Iron Boronmagnet block samar tsari, da daidaito na Magnetic Properties ya kamata a tsananin sarrafawa da kyau tsakanin tubalan da batches. Na biyu, a cikin aikin mashin ɗin, ya kamata a ɗauki kayan aikin injin da suka dace ko fasaha don biyan buƙatu na musamman akan sifar maganadisu, girman, haƙuri har ma da bayyanar wasu lokuta. Na uku, a cikin tsarin jiyya na saman, dole ne a gano ma'anar plating da nau'in sutura don isa girman bakin ciki da buƙatar haƙuri. Na hudu, a cikin tsarin dubawa, madaidaicin gwaji da fasaha na dubawa ya zama dole don sarrafawa da tabbatar da buƙatun maganadisu sun cika.

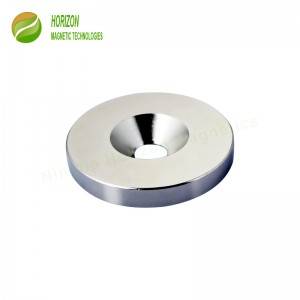

Horizon Magnetics yana da ƙwarewa mai yawa a cikin kera madaidaicin Neodymium maganadiso sama da shekaru goma, sannan mun fahimci menene da yadda ake sarrafa madaidaicin maganadisu. Domin ingantattun mashin ɗin, mun kasance muna ba da haɗin kai tare da tarurrukan bita da yawa waɗanda ke aiki don agogon hannu, ƙananan injina, da sauransu. Bayan haka, an sanye mu da kayan aikin injin na musamman, waɗanda aka keɓance su kuma mu ke tsara su. Ana amfani da murfin Parylene don tabbatar da juriya ga wasu madaidaicin Neodymium kamarkananan zobe maganadisotare da bakin ciki kaurin bango. Ana amfani da majigi da microscope sau da yawa don duba saman da girman don madaidaicin maganadisu.

A wannan lokacin, za mu iya sarrafa sintered Neodymium madaidaicin maganadisu tare da kauri na 0.15mm da haƙuri tsakanin 0.005 mm zuwa 0.02 mm. Mafi tsananin haƙuri shine, mafi girman farashin samarwa shine.