Domin axially magnetized SmCo Silinda maganadiso, wani lokacin su iya bukatar Multi sanduna magnetized ta tsawon ga wasu takamaiman aikace-aikace. Akwai dalilai da yawa don yanke shawara ko sandararriyar sandararriyar ta yi maganaSmCo magnetabu ne mai yuwuwa ko a'a, alal misali, buƙatun rata tsakanin sandunan maganadisu, girman maganadisu, ƙayyadaddun ƙayyadaddun maganadisu, kaddarorin maganadisu, da sauransu.NdFeB maganadisu. Idan girman maganadisu na SmCo ya yi girma sosai, magnetizer da ma'aunin maganadisu ba za su iya samar da isasshen filin magneti don yin magnetize SmCo maganadisu zuwa jikewa ba. Yawanci ana buƙatar kauri na magneto na SmCo ya zama ƙasa da 5 mm, kuma wani lokacin ya kamata a sarrafa Hcj a kusa ko bai wuce 15kOe ba. Kafin samar da jama'a, samfurin maganadisu da yawa dole ne a inganta shi ta cikakkun gwaje-gwajen abokan ciniki don biyan buƙatun aikace-aikacen.

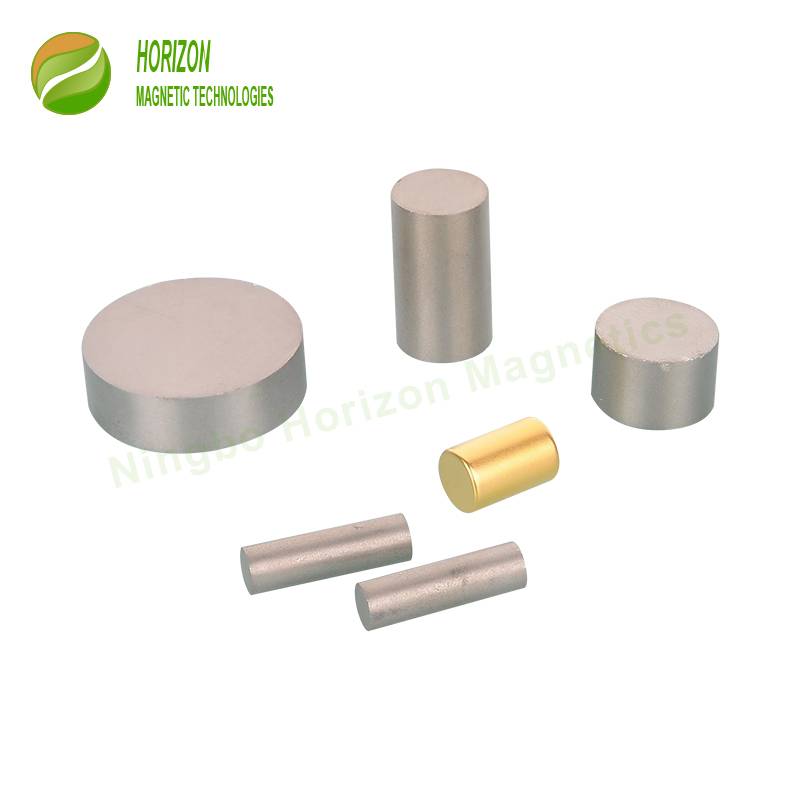

Wani lokaci, silinda SmCo maganadiso na iya buƙatar plating. Ba kamar sintered Neodymium maganadisu mai sauƙin oxidize, Samarium Cobalt maganadisu yana da kyau a lalata juriya saboda takamaiman kayan abun da ke ciki ba tare da Fe ko tare da kusan 15% baƙin ƙarfe ba. Saboda haka a mafi yawan aikace-aikace, shafi ba a bukatar SmCo maganadisu don hana lalata. Koyaya, a wasu filayen aikace-aikacen, ana buƙatar magnet SmCo da za a lulluɓe shi da zinari mai kyawu ko nickel don isa ga cikakkiyar siffa.

Lokacin da abokan ciniki suka yanke shawarar wane kayan maganadisu ya dace da aikace-aikacen su, suna kuma kula da kaddarorin jiki. Mai zuwa shine kaddarorin jiki don maganadisu na SmCo:

| Halaye | Madaidaicin Zazzabi Mai Juyawa 20-150ºC, α(Br) | Matsakaicin Zazzabi Mai Juyawa 20-150ºC, β(Hcj) | Coefficient na Thermal Expansion | Thermal Conductivity | Takamaiman Zafi | Curie Zazzabi | Ƙarfin Flexural | Yawan yawa | Hardness, Vickers | Juriya na Lantarki |

| Naúrar | %/ºC | %/ºC | ΔL/L da ºCx10-6 | kcal/mhrºC | ka/gºC | ºC | Mpa | g/cm3 | Hv | μΩ • cm |

| SmCo5 | -0.04 | -0.2 | //6⊥12 | 9.5 | 0.072 | 750 | 150-180 | 8.3 | 450-550 | 50-60 |

| Sm2Co17 | -0.03 | -0.2 | //9⊥11 | 8.5 | 0.068 | 850 | 130-150 | 8.4 | 550-650 | 80-90 |