Gabaɗaya magana, maganadisu zagaye da diamita ƙasa da 3mm, faifai ko toshe maganadisu tare da kauri wanda ya fi guntu 1mm, fasahar injina ko kula da ingancin za ta bambanta da maɗaukakin maɗaukaki na gabaɗaya, sannan ana iya ɗaukar su a matsayin ƙanana ko ƙaramin maganadisu.

La'akari da sinteredNdFeB maganadisuyana da wasu buƙatu daban-daban game da kaddarorin maganadisu da jiyya na saman daban da sauran sassan injina na gabaɗaya, ƙaramin maganadisu na Neodymium ba shi da sauƙin samarwa, na'ura ko dubawa don tabbatar da ingantaccen ingantaccen Neodymium micro magnet da ake buƙata.

Neodymium ƙaramin maganadisu ya fi wahalar samarwa fiye da yadda ake zato. Wasu mutane na iya tunanin cewa micro Neodymium maganadisu kawai yana buƙatar ƙarin kulawa yayin aikin injin, amma gaskiyar ta bambanta. Kaddarorin maganadisu, da ƙarfin filin maganadisu ko motsin maganadisu na iya bambanta babba don girman maganadisu iri ɗaya tare da kauri na bakin ciki. Yawancin mutane suna tunanin jurewar injina tsakanin kowane maganadisu yana haifar da girman maganadisu ko ƙarar tare da ƙaramin bambanci sannan ƙaramin bambanci a ƙarfin filin maganadisu. Duk da haka, ma'aunin maganadisu da ke tsakanin bakin maganadisu ya fi girma fiye da kauri, idan ba za a iya sarrafa kaddarorin maganadisu da kyau a cikin kowane shingen maganadisu ba, tsakanin kowane shingen maganadisu da kuma tsakanin ɗimbin tubalan maganadisu.

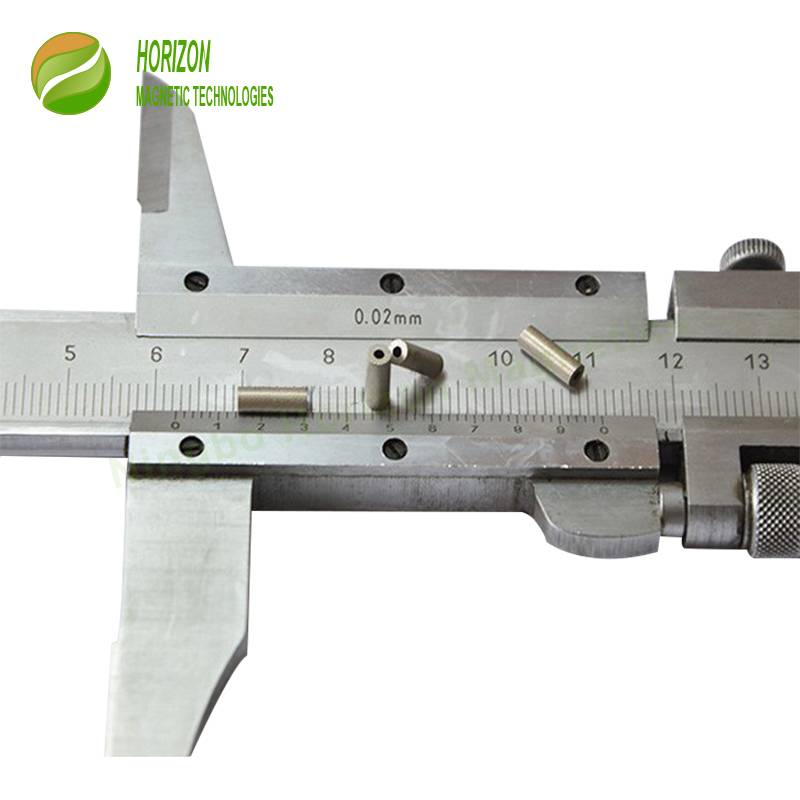

Godiya ga mudaidaitattun kayan aiki, a kan 10 shekara gogaggen machining injiniyoyi, da kuma gwaninta ilmi a wadata abokan ciniki tare da m kananan Neodymium maganadiso a cikin shekaru goma da suka wuce, Horizon Magnetics da ikon samar da sarrafa ingancin ta duk samar da QC matakai, ciki har da maganadisu block samar, machining, plating, magnetization, dubawa, da dai sauransu A wannan lokacin, za mu iya sarrafa sintered Neodymium micro maganadiso tare da kankanin diamita na 0.2mm da kankanin kauri da 0.15mm batu zuwa ga Neodymium maganadisu siffar da gaba daya girma a kowace hanya.